This spring assy are used for BPW truck air suspension parts .

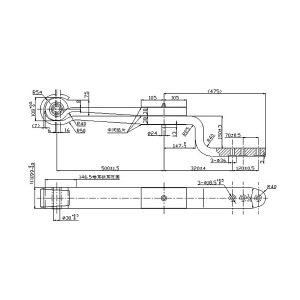

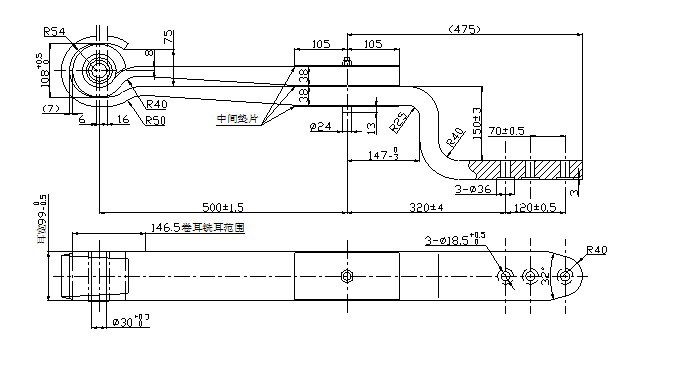

Spring Measurements Specs

Totally 2 blades , 3pc pads among blades ,1-2 blade Width(mm)*Thickness(mm): 100*38, The 1st blade Measurement 605 mm (Free Length Measurement) , The 2nd blade Measurement 975 mm Tolerance range within ±5mm . 1pc composite bushesØ30**100*Ø68*100 comes to install spring eyes .

All datas are obtained by measuring the new produce product .

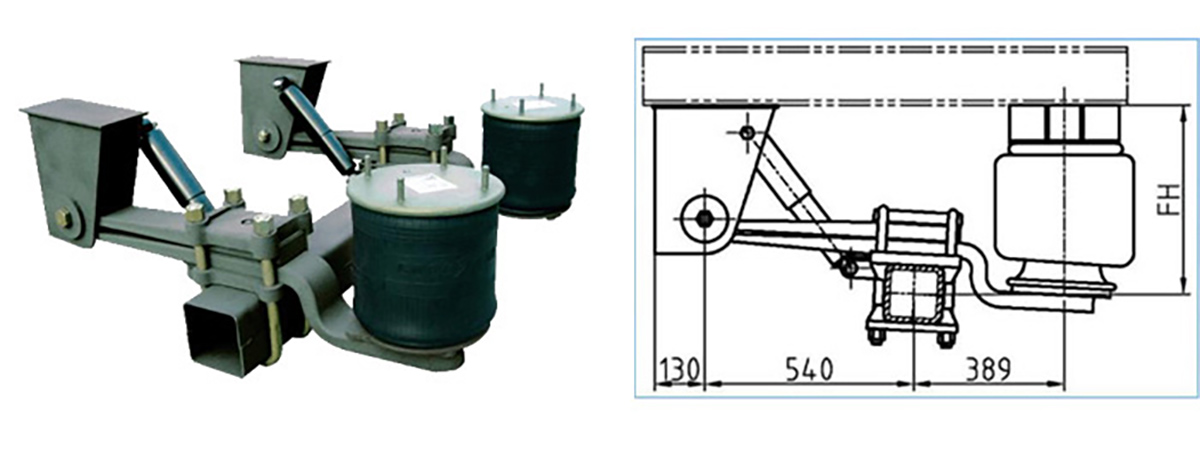

Air Suspension System Advantage

Air suspension systems came into existence in the early 1900s. Since then various technological improvements and increasing penetration have led to widespread adoption of this suspension technology. Further, air suspension systems are a type of suspension system that support the vehicle on the axles with the inclusion of air springs (air bags) as an alternative for steel springs or conventional leaf springs. Air suspension systems can increase the ability to transport loads by levelling the suspension. Additionally, they also reduce noise and vibration. Furthermore, in the market, integrated type of air suspension systems are being utilized in automotive owing to various cost related advantages. An air suspension system basically includes shock absorbers, air springs (ranging from 1 to 4), beam assembly, axle, brake system (excluded in the study), frame bracket, bushings and other mountings.

Air Suspension Detail Photos

We Provide Other Bpw Air Link Spring Part Number

880534/881386/886150/887701/881339/886118/881508/881381/880319/886117/880315/880368 and so on , we also can produce base on client’s drawings design .

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

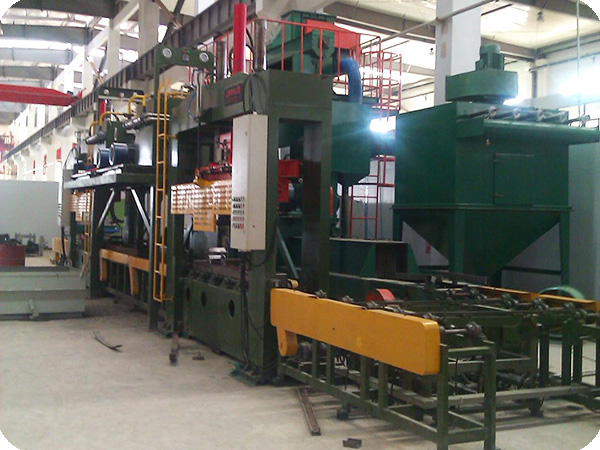

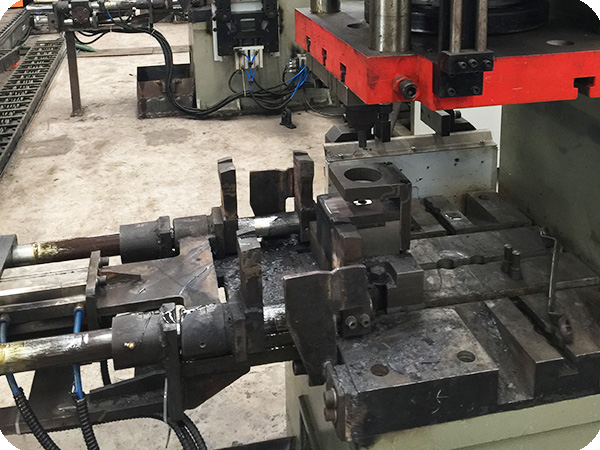

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )